Silicone oven moulds

Sweet or savory recipes, puddings, lasagnas and a lot more. The moulds in alimentary silicone are flexible, non-stick and very easy to use.

What shall I do

before cooking?

- Hand-clean the mould when you use it for the first time with hot water and soap, avoid using abrasive sponges.

- You can butter the mould a little bit to improve the non-stick and guarantee a healthy and dietetic food.

- Don’t worry for the contact with the ingredients: the silicone is tasteless and unscented.

- To pour the mixture, put at first the mould on the grill and then in the oven to not spill it.

- If the mixture has been frozen, you can pass the mould directly from the freezer to the oven: the silicone moulds have a resistance and a thermal stability between -40°C and +260°C.

And during the cooking?

- You can cook up to 260°C: the silicone has a very high resistance to temperature.

- Choose between a gas oven, a ventilated electrical one or the micro-wave, or between the fridge or the freezer.

- Do not heat an empty mould in the oven.

- Keep clear from a direct contact with the gas flames or electric plates.

- Don’t worry of the smell, the silicon is completely unscented and does not produce smoke.

- Compared to the cooking with a steel mould, keep the temperature of the oven under about 10°C and for over about 10 minutes.

After the cooking?

- Take the mould out of the oven and let the cake cool down for a few minutes.

- Delicately detach the edge of the mould before demoulding your cake.

- Thanks to the flexibility of the material, the details of the shape are accurately reproduced on the cake.

- Wash in the washing machine or hand clean it, keep clear from aggressive soaps and abrasive sponges.

- Put the mould wherever you prefer: you can fold it or flatten it; it can come back to its original shape immediately and it is a great space-saver which does not break nor gets damaged.

- If there are persistent remaining, boil the mould in the water for 10 minutes.

- Remember that if you used it properly, the mould in silicone guarantees up to 3000 cooking processes.

Discover the advantages of the silicone moulds

A really unbreakable material which presents a great resistance to wear and atmospheric agents.

The use of materials which are in contact with ingredients are regulated by very severe regulations, respected by the silicone. It is a non-toxic material.

The silicone moulds are thermally stable, they do not vary between -40°C and +260°C

Flexibility is a quality kept at low temperatures, even up to -40°C, and the electric insulation is one of their main features.

It can be used with the “defrost” or “cooking” function, but not with the “crisp” one.

Thanks to the flexibility of the mould, it can be fold or wrapped without it breaking and it has the great advantage of saving space.

Yes, the silicone moulds can be used to freeze and can go directly from the freezer to the micro-wave.

What to do after the purchase

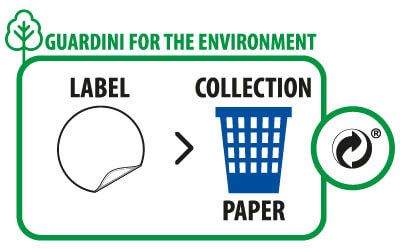

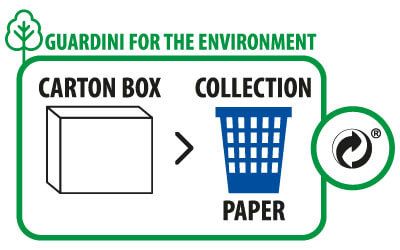

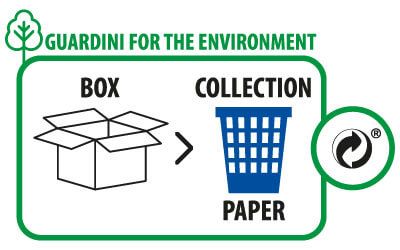

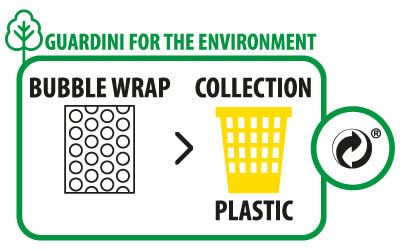

Our products are packed with different types of material that you can recycle properly following these handy tips: